charpy impact test formula derivation|charpy impact test diagram : distributors Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTM Confira o resultado da Lotofácil 2952 da Caixa Econômica Federal, o sorteio ocorre hoje e o prêmio do concurso 2952 da Lotofácil é de R$ 1.700.000,00. A Lotofácil 2952 é um dos sorteios mais esperados pelos entusiastas de loterias. Neste artigo, trazemos todas as informações sobre o resultado do sorteio e os números sorteados hoje.

{plog:ftitle_list}

WEBVilhena, Colorado do Oeste e Cerejeiras :: Rondônia (69) 3322 1307 [email protected]

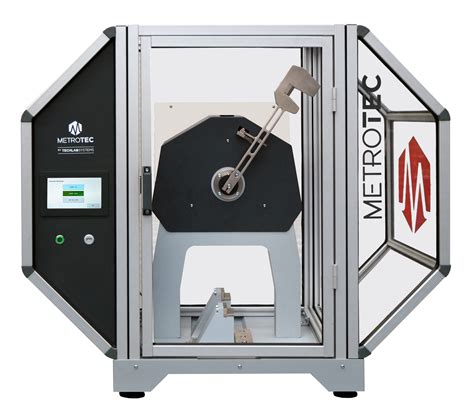

Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTMThe Charpy impact test, also known as the Charpy V-notch impact test, measures the energy a material absorbs when it fractures under an impact load. A pendulum in a Charpy impact test .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa.Charpy tests. Material impact toughness can be measured by various types of test such as the Charpy V-notch impact test, Izod test or K IC test. The most commonly used test is the Charpy .

The most common configuration for pendulum impact test are Izod and Charpy ones. The scope of these impact test is to measure the answer of a standard test specimen to the pendulum .The Charpy impact test is performed to evaluate the resistance of the metal to breakage by flexural shock or impact load according to standard test method ASTM D6110. The Charpy impact test, also commonly referred to as the Charpy V-notch test by material scientists, serves as a standardized high-strain rate examination to quantify the energy absorbed by a material upon fracture.Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .

The Charpy Impact Test is a standardized test method used to determine the amount of energy absorbed by a material during fracture. This is essential in understanding .

According to the standard test methods, the Charpy or Izod impact test can be employed to investigate the behavior of specified types of specimens under the impact conditions defined . The Charpy Impact Test, developed by Georges Charpy in 1905, is one of the most widely used tests to determine a material's notch toughness. It has been critical in material selection, especially in industries where impact resistance is crucial, such as automotive, aerospace, and construction.Tensile impact test procedures. The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test.Impact testing machine Standard charpy specimens (also called as ‘notch’ specimens) Furnace and thermocouple (to heat the specimen and increase its temperature) Liquid nitrogen (to lower the temperature of the specimen) Tongs (to hold and .

karl fischer volumetric titrator for moisture determination supplier

The objective of the Charpy impact test to ISO 148-1 is the determination of the impact energy and determination of the impact strength of a metal. The test indicates whether the metal is tough or brittle. In addition, the tough/brittle transition can be determined based on the temperature. Impact strength is a material characteristic value.

The Charpy impact test was invented in 1900 by Georges Augustin Albert Charpy (1865–1945), and it is regarded as one of the most commonly used test to evaluate the relative toughness of a material in a fast and economic way. The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load. This test continues to be .The Charpy impact test is performed to evaluate the resistance of the metal to breakage by flexural shock or impact load according to standard test method ASTM D6110. Fig 1: Charpy Test Apparatus. This test determines the amount of energy absorbed by a material during fracture. This absorbed energy is a measure of a given material’s notch . The main objective of this work is a more direct derivation of quasi-static fracture toughness from the Charpy impact test that can be directly compared to measured quasi-static fracture toughness .What is the charpy impact test – The charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material’s notch toughness. The objective of the charpy impact test ?? To determine the material resistance to impact from a .

Standard E 23, ―Standard Test Methods for Notched Bar Impact Testing of Metallic Materials‖. In 1901, a French researcher named Charpy published his work—the second publication in the world on pendulum machine testing—on notched bar pendulum impact tests [2]. Charpy’s tests used a pendulum impact machine based on the design developed .

A novel method for measuring the dynamic fracture toughness, K Id, using a Hopkinson pressure bar loaded instrumented Charpy impact test is presented in this paper.The stress intensity factor dynamic response curve (K I (t)−t) for a fatigue-precracked Charpy specimen is evaluated by means of an approximate formula.The onset time of crack .Impact of specimen thickness on fracture toughness. In materials science, fracture toughness is the critical stress intensity factor of a sharp crack where propagation of the crack suddenly becomes rapid and unlimited. A component's thickness affects the constraint conditions at the tip of a crack with thin components having plane stress conditions and thick components having .Computing Uncertainty for Charpy Impact Machine Test Results J. D. Splett,1 C. N. McCowan,2 H. K. Iyer,1 and C.-M. Wang1 National Institute of Standards and Technology 325 Broadway Boulder, CO 80305 This recommended practice guide demonstrates how to determine the uncertainty associated with mean absorbed energy of specimens tested on a Charpy .

Chapter 2 – Effects of Processing and Temperature on Charpy Impact Toughness in Metallic Glasses and Metallic Glass Matrix Composites Introduction to Charpy Testing Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTMThe Charpy impact test, also known as the Charpy V-notch impact test, measures the energy a material absorbs when it fractures under an impact load. A pendulum in a Charpy impact test machine is released to strike a notched specimen, and the amount of energy absorbed during the break is calculated.

Mechanical testing of welds. Philippa Moore, Geoff Booth, in The Welding Engineer s Guide to Fracture and Fatigue, 2015. 9.5 Charpy testing. The Charpy test measures the energy absorbed when a notched bar of material is struck with a fixed-weight pendulum swung from a given height. The absorbed energy (in joules) is also referred to as the impact toughness of the material. The Charpy impact test aka the Charpy V-notch test is aimed at determination of the energy absorbance of a material during fracture (Toshiro et al. 1986, Rossoll et al. 2002, Tanguy et al. 2005 .

An apparatus similar to the Charpy test is reliable in the derivation of values of energy and power for the calculation of impact resistance. . The Charpy impact test is a widely known test famous for its accuracy in measuring metallic and plastic materials. SB Russell and George Charpy introduced this in the 20th century to measure the .シャルピー衝撃試験機. シャルピー衝撃試験(シャルピーしょうげきしけん、英: Charpy impact test )とは、切り欠きのはいった角柱状の試験片に対して高速で衝撃を与えることで試験片を破壊し、破壊するために要したエネルギーと試験片の靭性を評価するための衝撃試験である。Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. The specimen is usually in the form of a thick beam with or without a notch and is supported freely at two ends, as shown in Fig. 3 (a).

A novel method for measuring the dynamic fracture toughness, K Id, using a Hopkinson pressure bar loaded instrumented Charpy impact test is presented in this paper. The stress intensity factor dynamic response curve (K I (t)−t) for a fatigue-precracked Charpy specimen is evaluated by means of an approximate formula. The onset time of crack initiation . The Instrumented Charpy impact test is a promising method for determining a material’s impact response. Stainless steel has higher impact energy absorption capacity, high tensile, and yield .4.3 The Charpy V-notch impact test in relation to other tests. 4.4 Factors influencing impact properties. 4.5 The Charpy V-notch impact test as a powerful tool for delivery control in steel specifications. 5 Information to be gained from the impact test. 6 Subsize test pieces.

s²), h is the initial height of the pendulum, h . Charpy impact test requirements for carbon steel and low alloy steel samples (listed in UCS-23) having a tensile stress . Charpy impact test standards. ASTM E23, ASTM D6110, ASTM A370, ASTM D256. ISO 13479, ISO 148-1. EN 10045-1, EN ISO 179-1 Izod impact testing. While Charpy impact testing is widespread for metals, Izod impact testing is more often used for plastics and other softer materials. In Izod testing, the notched specimen is positioned vertically instead .

Applications of Charpy Impact Test. In forging industry, the Charpy impact test can be used to determine the malleability and ductility of a material that is being forged. In the rubber industry, the test can be used for determining the shock absorbing ability of a type of rubber so that its proper application could be decided.Evaluation of dynamic fracture toughness KId by Hopkinson pressure bar loaded instrumented Charpy impact test . for a fatigue-precracked Charpy specimen is evaluated by means of an approximate formula. The onset time of crack initiation is experimentally detected using the strain gauge method. . stress wave theory enables applied specimen .

karl fischer volumetric titrator hi903 price supplier

charpy impact tester

Updated on: February 17th, 2024. In this Avatar World Codes Guide, we have shared all the working promo codes for the Mobile Game Avatar World that gives free Rewards .

charpy impact test formula derivation|charpy impact test diagram